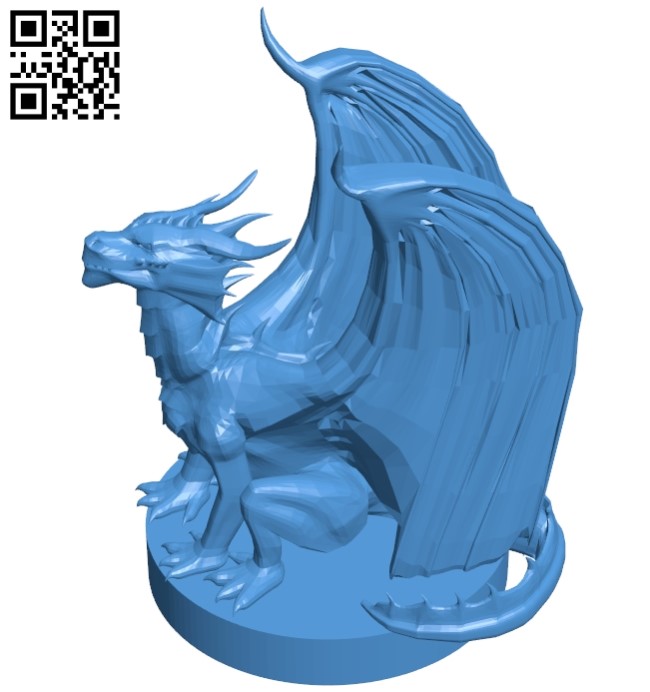

Once you’ve finished downloading the Dragon File, follow these steps: Printed 0.2 mm height, fill density 10%, and used PLA+. There is no need to add any additional support because the 3D-printed dragon file includes small supports that must be eliminated once printed. When setting the Gcode file, add membership brim or raft. The pieces have little contact surface to the bed, so it is very important to snug the bed printer. Consider those to be 1 to 3mm thick to join them.

It is for rapid prototyping, 3D printing, and computer-aided manufacturing. It is a 3D printing process and corresponding file type created by Chuck Hull at 3D Systems in the 1980s. Since its humble beginnings, many CAD software packages have adopted and supported the STL file format. When used with a 3D slicer, it allows a computer to communicate with the 3D printer hardware, printing a model. The STL (Standard Tessellation Language or STereoLithography) file format is the most commonly used format for 3D printing.

0 kommentar(er)

0 kommentar(er)